(COPE)/(TPEE) Thermoplastic copolyesters

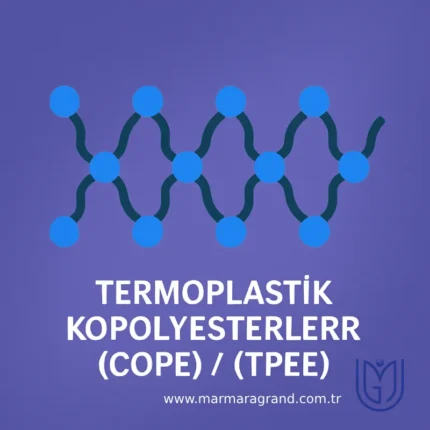

Thermoplastic Copolyesters (COPE), also known as Thermoplastic Polyester Elastomers (TPEE), are a class of thermoplastic elastomers (TPEs) that combine the mechanical properties of engineering plastics with the elasticity of rubber. They are composed of hard polyester crystalline segments and soft amorphous segments, providing a balance of strength, flexibility, and chemical resistance.

PropertiesThermoplastic Copolyesters (COPE), also known as Thermoplastic Polyester Elastomers (TPEE), combine the mechanical strength of engineering plastics with the flexibility and resilience of elastomers. They exhibit excellent elasticity, allowing them to return to their original shape after deformation, while also providing high tensile strength and durability. COPE materials offer outstanding chemical and solvent resistance, making them suitable for harsh environments. Their thermal stability enables them to maintain performance across a wide temperature range, with good low-temperature flexibility and resistance to heat aging. Additionally, they possess excellent abrasion resistance, impact strength, and fatigue resistance, ensuring longevity in demanding applications. With easy processability through injection molding, extrusion, and blow molding, COPE is widely used in automotive, industrial, consumer, and medical applications where a balance of toughness, flexibility, and chemical resistance is required.

StructureThermoplastic Copolyesters (COPE), also known as Thermoplastic Polyester Elastomers (TPEE), are a class of high-performance elastomers that combine the characteristics of both thermoplastics and rubbers. Their structure consists of alternating soft and hard segments, where the soft segments are typically made of aliphatic polyether or polyester, providing flexibility and elasticity, while the hard segments are composed of polyester blocks, offering strength, thermal resistance, and durability. This segmented block copolymer structure enables TPEEs to exhibit excellent mechanical properties, such as high tensile strength, impact resistance, and superior fatigue endurance. The presence of ester linkages in the hard phase contributes to chemical resistance and heat stability, while the soft phase ensures flexibility even at low temperatures. Due to this unique molecular architecture, COPEs find applications in various industries, including automotive, consumer goods, electrical components, and medical devices, where both resilience and processability are essential.

Applications

- Automotive: Used in air ducts, CVJ boots, bellows, gaskets, and wire coatings due to high heat and chemical resistance.

- Industrial & Mechanical: Employed in conveyor belts, hoses, seals, and grommets for durability and flexibility.

- Consumer Goods: Found in footwear soles, sports equipment, and flexible smartphone components for comfort and toughness.

- Electrical & Electronics: Used in cable insulation, connectors, and protective coatings due to excellent dielectric properties.

- Medical Devices: Applied in tubing, catheters, and soft-touch grips because of biocompatibility and sterilization resistance.

Advantages

- High Elasticity & Flexibility: Maintains shape and flexibility even under stress.

- Excellent Heat Resistance: Performs well at elevated temperatures compared to other TPEs.

- Superior Mechanical Strength: Offers high tensile strength, impact resistance, and fatigue endurance.

- Good Chemical Resistance: Resistant to oils, solvents, and many industrial chemicals.

- Wide Processing Window: Easily processed through injection molding, extrusion, and blow molding.

- Recyclable: More environmentally friendly than thermoset elastomers.

Disadvantages

- Higher Cost: More expensive than other thermoplastic elastomers (TPEs).

- Limited Low-Temperature Flexibility: Can become less flexible at extremely low temperatures compared to TPU.

- Absorbs Moisture: May require drying before processing to prevent defects.

- Processing Challenges: Requires precise temperature control during molding and extrusion

Linear Low Density Polyethylene (LLDPE)

LLDPE stands for Linear Low-Density Polyethylene. It is a type of polyethylene (a polymer made from ethylene monomers) that has short, linear branches in its molecular structure. This structure gives LLDPE unique properties compared to LDPE (Low-Density Polyethylene) and HDPE (High-Density Polyethylene).

StructureLLDPE has a unique linear molecular structure with short, controlled branches. This structure is different from LDPE (Low-Density Polyethylene), which has long and irregular branches. LLDPE consists of ethylene monomers (–CH₂–CH₂–) linked in a linear fashion. It has short, uniform side branches created by copolymerizing ethylene with α-olefins (like butene, hexene, or octene).These branches prevent the polymer chains from packing too tightly, giving LLDPE low density and flexibility.

PropertiesLLDPE (Linear Low-Density Polyethylene) is a versatile thermoplastic polymer known for its excellent flexibility, high impact resistance, and good tensile strength. it is slightly denser than LDPE but less rigid than HDPE, making it ideal for applications requiring toughness and stretchability. It has a high elongation at break (>500%), allowing it to withstand significant stretching without tearing. LLDPE exhibits excellent chemical resistance against acids, bases, and alcohols while maintaining low water absorption, making it suitable for moisture-sensitive applications. Thermally, it has a melting point of approximately 110–125°C and remains functional between -50°C and 60°C. Though it lacks inherent UV resistance, stabilizers can be added to improve durability under sunlight. Its ease of processing through extrusion, blow molding, and film manufacturing makes it widely used in plastic films, flexible tubing, cable insulation, and various molded products. While LLDPE is non-biodegradable, it is recyclable, contributing to sustainable material management.

Applications of Linear Low-Density Polyethylene (LLDPE)

- Packaging Industry:

- Stretch films and shrink wraps

- Plastic bags (grocery, trash, and industrial)

- Food packaging films (cling wraps, pouches)

- Agricultural Sector:

- Greenhouse films and mulch films

- Drip irrigation tubing and water storage tanks

- Industrial Applications:

- Pipes and fittings (flexible and durable)

- Cable insulation and protective coatings

- Industrial liners (chemical and water-resistant)

- Automotive Industry:

- Fuel tanks and hoses

- Interior soft components and protective covers

- Consumer & Household Products:

- Toys, containers, and household items

- Soft-touch grips and molded parts

- Medical & Pharmaceutical:

- Medical tubing and IV bags

- Sterile packaging films

Advantages of LLDPE

- Higher Flexibility and Toughness:

- More impact-resistant than LDPE

- Maintains durability even at low temperatures

- Excellent Chemical and Moisture Resistance:

- Resistant to acids, bases, and solvents

- Waterproof and corrosion-resistant

- Good Processability

- Lightweight and Cost-Effective

- Better Puncture and Tear Resistance:

- Ideal for thin film applications like stretch wraps

Disadvantages of LLDPE

- Lower Heat Resistance:

- Softens and deforms at high temperatures

- Not suitable for high-temperature applications

- Poor UV Stability:

- Requires UV stabilizers for outdoor use, or it degrades over time

- Lower Stiffness Compared to HDPE:

- Less rigid, making it unsuitable for structural applications

- Limited Gas Barrier Properties:

- Not ideal for gas-tight packaging applications

- Difficult to Process in Some Applications:

- Requires higher processing temperatures compared to LDPE

Nylon 6

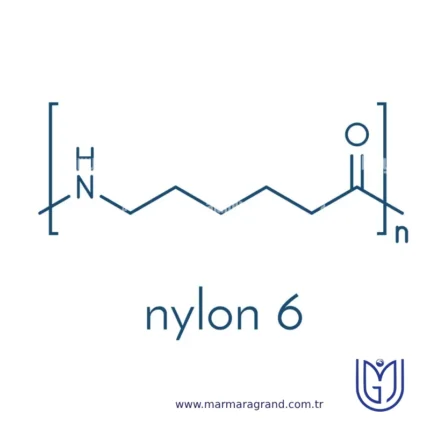

Nylon 6 is a synthetic engineering thermoplastic belonging to the polyamide (PA) family. It is widely used for its high strength, durability, thermal resistance, and chemical stability. Nylon 6 is synthesized from a single monomer, caprolactam, through ring-opening polymerization. This makes Nylon 6 easier to produce and process.

PropertiesNylon 6 is a strong, lightweight, and durable engineering thermoplastic known for its excellent mechanical and thermal properties. It has high tensile strength, toughness, and impact resistance, making it suitable for demanding applications. It also exhibits good wear resistance, low friction, and excellent abrasion resistance, which enhances its longevity in mechanical parts. Nylon 6 has a melting point of approximately 220°C and maintains stability over a wide temperature range. It offers good chemical resistance to oils, greases, and many solvents but is sensitive to strong acids and bases. One of its notable characteristics is its high moisture absorption, which can affect its mechanical strength and dimensional stability. Nylon 6 also has good electrical insulating properties, making it useful in electrical and electronic applications. Additionally, it is easily processable through injection molding, extrusion, and fiber spinning, allowing for its widespread use in textiles, automotive components, and industrial applications.

StructureNylon 6 is a synthetic polymer belonging to the polyamide family, characterized by its repeating units derived from caprolactam through a ring-opening polymerization process. The molecular structure of Nylon 6 consists of a linear chain of amide (–CONH–) linkages interspersed with six-carbon alkyl segments, forming a highly regular and symmetrical backbone that contributes to its notable mechanical strength, thermal stability, and chemical resistance. Unlike Nylon 6,6, which is synthesized from two different monomers, Nylon 6 is synthesized from a single monomer, ε-caprolactam, which undergoes polymerization through successive opening of the lactam ring, resulting in a continuous chain structure. The presence of hydrogen bonding between adjacent polymer chains enhances intermolecular interactions, leading to high crystallinity and improved tensile properties. This structural arrangement imparts Nylon 6 with desirable characteristics such as high flexibility, durability, and resistance to abrasion, making it widely utilized in textiles, engineering plastics, and industrial applications.

Applications of Nylon 6

- Textiles and Fabrics: Nylon 6 is widely used in the textile industry to produce items such as hosiery, swimwear, activewear, and undergarments due to its elasticity, strength, and smooth texture.

- Industrial Uses: Its high tensile strength and abrasion resistance make Nylon 6 suitable for manufacturing ropes, fishing nets, conveyor belts, and tire cords.

- Automotive Components: Nylon 6 is utilized in producing various automotive parts, including gears, bearings, and under-the-hood components, because of its durability and thermal stability.

- Consumer Goods: Common household items like toothbrush bristles, combs, and kitchen utensils are often made from Nylon 6 due to its resilience and ease of molding.

- Engineering Plastics: Nylon 6 is used in the production of engineering plastics for applications such as gears, bearings, and other mechanical components, owing to its strength and wear resistance.

Advantages of Nylon 6

- High Strength and Durability: Nylon 6 exhibits excellent tensile strength, making it suitable for products requiring long-lasting performance.

- Flexibility and Elasticity: The material offers good flexibility and can return to its original shape after stretching, which is beneficial for textile applications.

- Chemical Resistance: Nylon 6 is resistant to a wide range of chemicals, including oils and solvents, enhancing its suitability for various industrial applications.

- Thermal Resistance: With a high melting point, Nylon 6 can withstand elevated temperatures, making it appropriate for applications involving heat exposure.

- Lightweight: Nylon 6 is lighter than many metals, which is advantageous in applications where weight reduction is desired.

Disadvantages of Nylon 6

- Moisture Absorption: Nylon 6 is hygroscopic and can absorb moisture from the environment, leading to dimensional changes and potential degradation of mechanical properties.

- UV Sensitivity: Prolonged exposure to ultraviolet light can cause Nylon 6 to degrade, leading to discoloration and loss of strength.

- Lower Impact Resistance: Compared to some other engineering plastics, Nylon 6 may exhibit lower impact resistance, which could limit its use in high-impact applications.

- Processing Challenges: Nylon 6 requires careful control during processing, as it is sensitive to moisture and can degrade if not properly dried before molding.

Polyarylate (PAR)

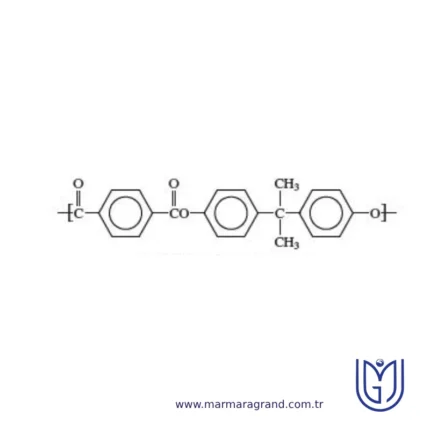

Polyarylate (PAR) is a type of high-performance aromatic polyester known for its excellent thermal stability, mechanical strength, and resistance to chemicals and UV radiation. It is commonly used in engineering applications where durability and heat resistance are required.

Structure

Polyarylate (PAR) is a high-performance thermoplastic polymer composed of repeating aromatic ester units in its backbone. Its structure consists of aromatic rings (benzene) connected by ester (-COO-) linkages, giving it excellent thermal and mechanical properties. The presence of these rigid benzene rings enhances the polymer’s strength, dimensional stability, and resistance to heat and UV radiation. Unlike aliphatic polyesters, which have flexible carbon chains, the rigid aromatic backbone of polyarylates prevents easy molecular rotation, making the material more heat-resistant and mechanically robust. A common type of polyarylate is based on bisphenol A (BPA) and terephthalic or isophthalic acid, forming a polymer with a high glass transition temperature and excellent durability. This unique structure makes polyarylates ideal for applications requiring transparency, heat resistance, and chemical stability, such as optical lenses, automotive parts, and electronic components.

Properties

Polyarylate (PAR) exhibits a combination of high thermal stability, mechanical strength, and chemical resistance, making it a valuable engineering thermoplastic. It has a high glass transition temperature (Tg) of around 180°C, allowing it to retain its shape and strength under elevated temperatures. Its excellent mechanical properties, including high tensile strength and toughness, make it resistant to wear and impact. Additionally, PAR has outstanding UV and weather resistance, preventing degradation when exposed to sunlight, making it suitable for outdoor applications. The polymer is also chemically resistant to oils, acids, and solvents, ensuring durability in harsh environments. Many grades of polyarylate are optically transparent, making them useful for lenses and display applications. Furthermore, it exhibits good dimensional stability and low creep, ensuring reliability in precision applications like electronic components and automotive parts. These properties collectively make PAR an ideal material for high-performance applications where strength, heat resistance, and durability are essential.

Applications of Polyarylate (PAR):

- Electronics & Electrical Components – Used in connectors, insulators, and circuit boards due to its heat and electrical resistance.

- Automotive Parts – Ideal for components exposed to high temperatures and mechanical stress.

- Aerospace Industry – Used in structural components for its lightweight and high durability.

- Optical Lenses & Displays – Some grades are optically clear, making them suitable for eyewear, camera lenses, and LCD panels.

- Medical Devices – Resistant to sterilization methods and biocompatible for certain medical applications.

- Industrial Machinery – Used in gears, seals, and mechanical components requiring high strength and wear resistance.

- Consumer Goods – Found in high-end cookware, protective coatings, and UV-resistant outdoor products.

- High heat resistance – Maintains strength at elevated temperatures.

- Excellent mechanical strength – High tensile strength and impact resistance.

- UV and weather resistance – Ideal for outdoor applications without degradation.

- Good chemical resistance – Withstands exposure to oils, acids, and solvents.

- Optical clarity – Some grades are transparent, useful for lenses and displays.

- Dimensional stability – Low creep and high rigidity for precision applications.

- Expensive – Higher cost compared to conventional plastics.

- Difficult processing – Requires specialized equipment and high processing temperatures.

- Brittle in some conditions – May be prone to stress cracking under certain loads.

- Limited availability – Less commonly used than other engineering plastics, leading to fewer commercial grades.

PolyArylEtherKetone (PAEK)

PolyArylEtherKetone (PAEK) is a family of high-performance, semi-crystalline thermoplastics known for their excellent mechanical properties, thermal stability, and chemical resistance. These polymers contain aromatic rings connected by ether (-O-) and ketone (-CO-) linkages, which contribute to their strength and durability.

Structure

The structure of PolyArylEtherKetone (PAEK) consists of a repeating backbone of aromatic rings (aryl groups) connected by ether (-O-) and ketone (-CO-) linkages. These alternating ether and ketone groups provide a unique combination of flexibility and rigidity, contributing to the polymer's high thermal stability, chemical resistance, and mechanical strength. The presence of aromatic rings enhances structural integrity, making the polymer highly resistant to degradation under extreme conditions. The ether linkages add flexibility to the molecular chain, improving processability, while the ketone groups increase the polymer’s resistance to heat and oxidation. The semi-crystalline nature of PAEK arises from the ability of the polymer chains to pack efficiently in an ordered manner, leading to excellent wear resistance and high mechanical performance. Different types of PAEK, such as PEEK, PEK, and PEKK, vary in the arrangement and proportion of these functional groups, influencing their thermal and mechanical properties. This unique molecular structure makes PAEK an ideal choice for high-performance applications in aerospace, medical, automotive, and industrial sectors.

Properties

PolyArylEtherKetone (PAEK) is a high-performance, semi-crystalline thermoplastic known for its exceptional mechanical, thermal, and chemical properties. It exhibits excellent strength, stiffness, and wear resistance, making it ideal for demanding applications in aerospace, automotive, medical, and oil and gas industries. PAEK has outstanding thermal stability, withstanding continuous use temperatures of up to 250°C, while also demonstrating remarkable resistance to chemicals, including acids, bases, and organic solvents. It possesses low moisture absorption, ensuring dimensional stability even in humid environments. Furthermore, PAEK offers excellent fatigue resistance, making it suitable for long-term load-bearing applications. Its inherent flame retardancy and low smoke emission enhance safety in high-temperature environments. Additionally, PAEK maintains excellent electrical insulation properties, making it valuable for electronic and electrical applications. These unique characteristics make PAEK an advanced material choice for extreme engineering conditions.

Applications of PolyArylEtherKetone (PAEK):

- Aerospace & Automotive: Used in structural components, bearings, and bushings due to its lightweight, high strength, and temperature resistance.

- Medical Devices: Ideal for implants, surgical instruments, and dental components due to biocompatibility and sterilization resistance.

- Oil & Gas Industry: Used in seals, valves, and insulators for its excellent chemical and high-temperature resistance.

- Electronics & Electrical: Utilized in connectors, insulators, and semiconductor manufacturing for its electrical insulation and heat resistance.

- Industrial & Manufacturing: Used in gears, pumps, and wear-resistant parts due to its high mechanical strength and low friction.

- High Thermal Stability: Can withstand continuous temperatures up to 250°C.

- Excellent Mechanical Properties: High strength, stiffness, and impact resistance.

- Chemical Resistance: Withstands harsh chemicals, acids, and solvents.

- Low Moisture Absorption: Ensures dimensional stability in humid environments.

- Good Wear & Fatigue Resistance: Ideal for long-term, high-load applications.

- Flame Retardant & Low Smoke Emission: Enhances safety in high-temperature applications.

- Biocompatibility: Suitable for medical implants and surgical devices.

- High Cost: More expensive than conventional plastics and some high-performance polymers.

- Difficult Processing: Requires high temperatures and specialized equipment for manufacturing.

- Limited Availability: Not as widely produced as other engineering plastics, leading to supply constraints.

- Brittleness at Low Temperatures: Can become less impact-resistant in extreme cold conditions.

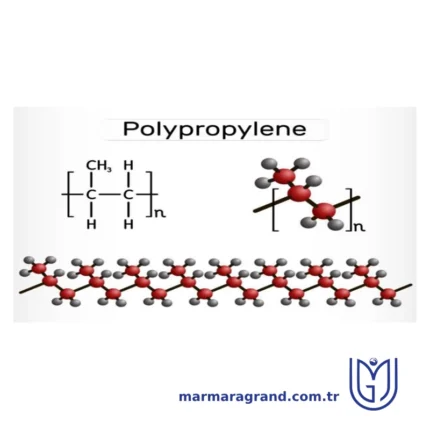

PolyPropylene (PP Chemical)

Polypropylene (PP) is one of the most widely used thermoplastic polymers, known for its high strength, chemical resistance, and versatility. It is used in industries ranging from packaging and textiles to automotive and medical applications.

Structure of Polypropylene (PP)Polypropylene (PP) is a semi-crystalline thermoplastic polymer derived from propene (C₃H₆) monomers through the polymerization process.

- Molecular Structure:

- Composed of repeating propylene units (C₃H₆) linked together in a chain-like structure.

- Exists in three main forms:

- Isotactic PP – Most commonly used, with all methyl groups (CH₃) aligned on one side of the polymer chain, resulting in high crystallinity and strength.

- Syndiotactic PP – Alternating arrangement of methyl groups, making it more flexible but less crystalline.

- Atactic PP – Random arrangement of methyl groups, leading to an amorphous structure with low strength.

- Polymerization Process:

- Polypropylene is synthesized using Ziegler-Natta catalysts or metallocene catalysts in industrial polymerization reactions.

- It is classified as a thermoplastic, meaning it can be melted and reshaped multiple times without significant degradation.

Properties of Polypropylene (PP)Polypropylene possesses a combination of mechanical, thermal, and chemical properties, making it ideal for diverse applications.

1. Mechanical Properties:

✔ High Tensile Strength – Strong yet lightweight, making it ideal for packaging and textiles. ✔ Impact Resistance – Can withstand moderate shocks and impacts. ✔ Good Elasticity & Flexibility – Suitable for films, fibers, and flexible containers.2. Thermal Properties:

✔ High Melting Point (~160°C – 170°C) – More heat-resistant than polyethylene (PE). ✔ Low Thermal Conductivity – Acts as an insulating material. ✔ Resistant to Temperature Fluctuations – Can handle both hot and cold environments.3. Chemical Properties:

✔ Resistant to Acids, Alkalis, and Solvents – Does not degrade easily when exposed to chemicals. ✔ Low Water Absorption – Maintains mechanical properties in humid environments. ✔ Good Fatigue Resistance – Ideal for repeated bending applications like hinges.4. Electrical Properties:

✔ Excellent Electrical Insulation – Used in wires, cables, and electrical components.5. Environmental Properties:

✔ Recyclable (#5 plastic code) – Can be reused in eco-friendly applications. ✔ UV Sensitivity – Can degrade when exposed to prolonged UV radiation unless treated with stabilizers.Applications of Polypropylene (PP)

- Packaging Industry

- Textile Industry

- Automotive Industry

- Medical & Healthcare Applications

- Household & Consumer Products

- Industrial Applications

Advantages of Polypropylene (PP)✔ Lightweight & Strong – Provides durability without adding extra weight. ✔ Excellent Chemical Resistance – Withstands exposure to acids, bases, and solvents. ✔ High Heat Resistance – Can be used in microwaves and hot water applications. ✔ Waterproof & Moisture-Resistant – Ideal for food packaging and textiles. ✔ Recyclable & Eco-Friendly – Can be reused, reducing plastic waste. ✔ Affordable & Cost-Effective – Inexpensive compared to other polymers. ✔ Non-Toxic & Safe – Used in medical and food-grade applications.

Disadvantages of Polypropylene (PP)✘ UV Degradation – Can become brittle when exposed to sunlight for long periods unless UV stabilizers are added. ✘ Low Impact Resistance at Low Temperatures – Can crack in extremely cold conditions. ✘ Flammability – Easily combustible and requires flame retardants for certain applications. ✘ Difficult to Paint or Glue – Requires special surface treatments for adhesion. ✘ Limited Transparency – Unlike PET, PP is not completely clear. ✘ Environmental Concerns – Though recyclable, it is not biodegradable, leading to plastic waste issues.

Textile Grade

Textile grade refers to materials that are specifically designed and processed for textile applications, ensuring optimal performance in fabric production. These materials can be natural (like cotton, wool, silk) or synthetic (like polyester, nylon, acrylic).

- Molecular Structure:

- Natural fibers have a cellulose-based (plant fibers) or protein-based (animal fibers) molecular structure.

- Synthetic fibers are often derived from polymer chains, such as polyethylene terephthalate (PET) in polyester.

- Fiber Morphology:

- Fibers are classified as filament (long, continuous fibers like silk) or staple (short fibers like cotton).

- Processing techniques such as spinning, weaving, and knitting alter fiber orientation for enhanced strength and flexibility.

- Surface Treatment:

- Textile grade materials undergo chemical treatments such as dyeing, anti-static coating, moisture-wicking finishes, and UV protection to enhance their functionality.

PropertiesTextile grade materials possess distinct characteristics that make them suitable for various applications:

1. Mechanical Properties

✔ High Tensile Strength – Ensures durability and resistance to tearing. ✔ Elasticity – Some fibers (like spandex) stretch and recover their shape. ✔ Abrasion Resistance – Important for heavy-use applications like upholstery and workwear.2. Thermal Properties

✔ Heat Resistance – Some fibers (e.g., aramid, wool) withstand high temperatures. ✔ Low Melting Point – Certain synthetics (e.g., polyester) require controlled heat processing.3. Chemical Properties

✔ Moisture-Wicking – Polyester and nylon repel moisture, keeping fabrics dry. ✔ Chemical Resistance – Some textile grades resist acids, alkalis, and solvents. ✔ UV Protection – Certain fibers (e.g., acrylic) naturally block UV rays.4. Environmental Properties

✔ Biodegradability – Natural fibers decompose over time, unlike synthetics. ✔ Sustainability – Eco-friendly textile grades include organic cotton, recycled polyester, and bamboo fibers.ApplicationsTextile grade materials are used across multiple industries, including fashion, home textiles, and technical applications.

1. Apparel Industry

- Clothing – Shirts, pants, jackets, and sportswear.

- Performance Fabrics – Moisture-wicking athletic wear, compression garments.

- Luxury Textiles – Silk, high-thread-count cotton, and premium synthetic blends.

2. Home Textiles

- Upholstery – Durable fabrics for sofas, curtains, and carpets.

- Bedding – Sheets, blankets, and pillowcases.

- Towels & Linens – Cotton-based materials for comfort and absorbency.

3. Industrial & Technical Textiles

- Automotive Textiles – Car seats, airbags, and interior linings.

- Medical Textiles – Surgical gowns, bandages, and antimicrobial fabrics.

- Protective Gear – Fire-resistant clothing (e.g., Nomex), bulletproof vests (Kevlar).

4. Eco-Friendly & Sustainable Applications

- Recycled Textiles – Upcycled polyester from plastic bottles.

- Organic Fibers – Bamboo, hemp, and organic cotton for sustainable fashion.

AdvantagesDurability – Textile grade materials are engineered for longevity. Versatility – Suitable for various applications, from fashion to industry. Lightweight & Comfortable – Many textiles are breathable and easy to wear. Easy Maintenance – Many fibers resist stains, wrinkles, and shrinkage. Cost-Effective – Mass production of synthetics reduces costs. Sustainability Options – Growing availability of eco-friendly textile grades.

DisadvantagesEnvironmental Concerns – Many synthetic fibers are non-biodegradable and contribute to plastic pollution. Flammability – Some textiles require fire-resistant treatments for safety. Chemical Sensitivity – Certain materials degrade when exposed to strong detergents, acids, or UV light. Heat Sensitivity – Synthetic fibers like polyester melt at high temperatures, limiting ironing options. Moisture Absorption Issues – Some fibers retain or repel moisture excessively, impacting comfort.