Linear Low Density Polyethylene (LLDPE)

LLDPE stands for Linear Low-Density Polyethylene. It is a type of polyethylene (a polymer made from ethylene monomers) that has short, linear branches in its molecular structure. This structure gives LLDPE unique properties compared to LDPE (Low-Density Polyethylene) and HDPE (High-Density Polyethylene).

StructureLLDPE has a unique linear molecular structure with short, controlled branches. This structure is different from LDPE (Low-Density Polyethylene), which has long and irregular branches. LLDPE consists of ethylene monomers (–CH₂–CH₂–) linked in a linear fashion. It has short, uniform side branches created by copolymerizing ethylene with α-olefins (like butene, hexene, or octene).These branches prevent the polymer chains from packing too tightly, giving LLDPE low density and flexibility.

PropertiesLLDPE (Linear Low-Density Polyethylene) is a versatile thermoplastic polymer known for its excellent flexibility, high impact resistance, and good tensile strength. it is slightly denser than LDPE but less rigid than HDPE, making it ideal for applications requiring toughness and stretchability. It has a high elongation at break (>500%), allowing it to withstand significant stretching without tearing. LLDPE exhibits excellent chemical resistance against acids, bases, and alcohols while maintaining low water absorption, making it suitable for moisture-sensitive applications. Thermally, it has a melting point of approximately 110–125°C and remains functional between -50°C and 60°C. Though it lacks inherent UV resistance, stabilizers can be added to improve durability under sunlight. Its ease of processing through extrusion, blow molding, and film manufacturing makes it widely used in plastic films, flexible tubing, cable insulation, and various molded products. While LLDPE is non-biodegradable, it is recyclable, contributing to sustainable material management.

Applications of Linear Low-Density Polyethylene (LLDPE)

- Packaging Industry:

- Stretch films and shrink wraps

- Plastic bags (grocery, trash, and industrial)

- Food packaging films (cling wraps, pouches)

- Agricultural Sector:

- Greenhouse films and mulch films

- Drip irrigation tubing and water storage tanks

- Industrial Applications:

- Pipes and fittings (flexible and durable)

- Cable insulation and protective coatings

- Industrial liners (chemical and water-resistant)

- Automotive Industry:

- Fuel tanks and hoses

- Interior soft components and protective covers

- Consumer & Household Products:

- Toys, containers, and household items

- Soft-touch grips and molded parts

- Medical & Pharmaceutical:

- Medical tubing and IV bags

- Sterile packaging films

Advantages of LLDPE

- Higher Flexibility and Toughness:

- More impact-resistant than LDPE

- Maintains durability even at low temperatures

- Excellent Chemical and Moisture Resistance:

- Resistant to acids, bases, and solvents

- Waterproof and corrosion-resistant

- Good Processability

- Lightweight and Cost-Effective

- Better Puncture and Tear Resistance:

- Ideal for thin film applications like stretch wraps

Disadvantages of LLDPE

- Lower Heat Resistance:

- Softens and deforms at high temperatures

- Not suitable for high-temperature applications

- Poor UV Stability:

- Requires UV stabilizers for outdoor use, or it degrades over time

- Lower Stiffness Compared to HDPE:

- Less rigid, making it unsuitable for structural applications

- Limited Gas Barrier Properties:

- Not ideal for gas-tight packaging applications

- Difficult to Process in Some Applications:

- Requires higher processing temperatures compared to LDPE

Low Density PolyEthylene (LDPE)

LDPE film grade is divided into several types, including general-purpose film, high-transparency film, heavy-duty film, shrink film, and cast film. These materials possess superior physical and mechanical properties, along with high chemical stability and excellent electrical insulation. They also feature low water vapor permeability and outstanding processability, making them ideal for various applications. Films made from these resins provide exceptional clarity and strong resistance to aging, ensuring durability and long-lasting performance.

StructureLDPE (Low-Density Polyethylene) film grade is a thermoplastic polymer made from ethylene monomers (C₂H₄) through a high-pressure polymerization process. Its molecular structure is characterized by high branching, which gives it its unique properties. Key Structural Features: Highly Branched Polymer:

- LDPE has short-chain and long-chain branches, preventing tight packing of polymer chains.

- Due to branching, LDPE has low crystallinity (~40–50%), making it soft and transparent.

- It is more flexible and stretchable than HDPE (High-Density Polyethylene).

- LDPE has a broad molecular weight distribution, contributing to good melt strength and processability in film extrusion.

PropertiesLow-Density Polyethylene (LDPE) film grade is a highly flexible and lightweight material known for its excellent elongation, impact resistance, and transparency. With a density ranging from 0.915 to 0.930 g/cm³, it offers good clarity but can appear slightly hazy. It has a relatively low melting point of around 105–115°C and remains flexible even at sub-zero temperatures, making it suitable for various applications. LDPE exhibits moderate tensile strength (8–17 MPa) and exceptional elongation at break (100–600%), ensuring durability and resilience. While it provides a good moisture barrier, its gas barrier properties are poor, allowing oxygen and CO₂ to pass through. Chemically, LDPE resists acids, bases, and alcohols but is vulnerable to hydrocarbons. Its excellent heat-sealing properties make it ideal for packaging applications, including food wrap, shrink films, and shopping bags. Additionally, it is widely used in agricultural films, protective industrial films, and medical applications such as IV bags and tubing. LDPE is typically processed through blown or cast film extrusion, operating within a temperature range of 160–220°C. However, due to its susceptibility to UV degradation, stabilizers are often added for outdoor applications. Overall, LDPE film grade is a versatile and cost-effective material, valued for its flexibility, sealability, and ease of processing.

Applications

- Packaging

- Used for manufacturing flexible packaging films (e.g., shopping bags, wraps, and pouches).

- Food packaging, including wraps, freezer bags, and shrink films.

- Industrial packaging for wrapping materials, products, and protective covers.

- Agricultural Use

- Greenhouse films for agricultural purposes, creating protective environments for plants.

- Mulch films for soil coverage and weed control.

- Consumer Products

- Plastic bags for grocery stores, retail packaging, and garbage bags.

- Cling films for food preservation and covering items.

- Disposable liners for various containers.

- Construction

- Vapor barriers in buildings, preventing moisture from seeping into structures.

- Covers for construction materials during storage or transportation.

- Medical Use

- Sterile packaging for medical devices, equipment, and pharmaceuticals.

- Medical drapes and covers.

Advantages

- Flexibility

- LDPE film is highly flexible and can be stretched without breaking.

- Transparency

- Offers high clarity and transparency, making it ideal for packaging.

- Chemical Resistance

- Good resistance to chemicals, oils, and greases.

- Low Cost

- Relatively affordable material, making it a cost-effective solution for many applications.

- Ease of Processing

- Easy to process with methods like extrusion, injection molding, and blow molding.

- Lightweight

- Lightweight material, reducing transportation and handling costs.

- Moisture Resistance

- Water-resistant properties, providing good moisture protection in packaging.

Disadvantages

- Low Strength

- Low tensile strength and can tear easily under stress or load.

- Limited Heat Resistance

- Has a low melting point, which limits its use in high-temperature environments.

- Environmental Impact

- Non-biodegradable and contributes to plastic pollution if not recycled properly.

- Poor UV Resistance

- Can degrade when exposed to UV light, leading to brittleness and color fading over time.

- Low Barrier Properties

- Not ideal for barrier applications like gas or vapor resistance compared to other materials like BOPP or PET.

Rotational Molding

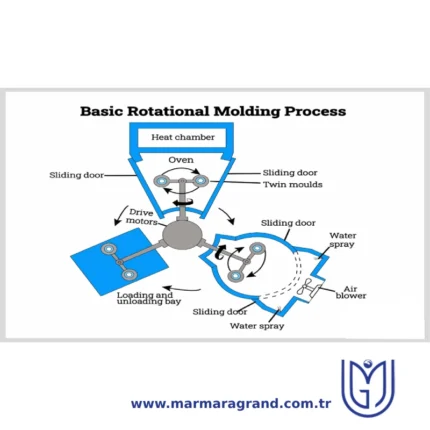

The rotational molding process is a straightforward yet effective method. In this technique, a plastic material, typically in powdered form, is placed inside a hollow mold. This mold is usually made of cast aluminum or fabricated from sheet steel. Once sealed, the mold rotates slowly around two axes. Simultaneously, it is heated inside an oven while continuously rotating. As the temperature rises, the plastic powder melts and evenly coats the inner surface of the mold. When the plastic has completely liquefied, the mold is transferred to a cooling station, where it is cooled using air or occasionally a fine mist of water. During this phase, the plastic gradually solidifies and takes its final shape. Once the material has cooled sufficiently and detaches from the mold’s surface, the process is halted, and the finished product is removed from the mold.

Types of rotational moldingClamshell Rotational Molding

- Uses a single-arm machine with an oven and cooling chamber combined.

- Best for smaller production runs or prototyping.

- Less efficient than multi-arm machines but requires less space.

- Designed for long and narrow products like kayaks and boats.

- The mold rotates on one axis while rocking back and forth on another axis.

- Ideal for making large, elongated parts with uniform wall thickness.

- Features two arms that shuttle between heating and cooling stations.

- Allows simultaneous molding and cooling, increasing production efficiency.

- Suitable for medium to large-scale manufacturing.

- Uses a vertical rotation system rather than the traditional horizontal axis.

- Provides more control over material distribution.

- Less common but useful for specific applications requiring precise thickness control.

- The most common and efficient type, often with three to four arms.

- Molds move continuously between loading, heating, cooling, and unloading stations.

- Ideal for high-volume production and large-scale manufacturing.

Advantages of rotational molding

- Cost-Effective Tooling – Molds are cheaper compared to injection or blow molding.

- Uniform Wall Thickness – Ensures even material distribution with no weak spots.

- Seamless and Hollow Structures – Produces one-piece parts without welds or joints.

- Design Flexibility – Allows for complex shapes, undercuts, and integrated features.

- Strong and Durable Products – High impact resistance with reinforced corners.

- Wide Range of Materials – Can use polyethylene (PE), polypropylene (PP), and nylon.

- Minimal Material Waste – Excess plastic can be recycled and reused.

- Large Part Capability – Ideal for tanks, containers, and oversized plastic products.

- Consistent and Repeatable Process – Ensures uniformity in mass production.

- Eco-Friendly Process – Lower energy consumption and recyclable materials.

Disadvantages of rotational molding

- Longer Cycle Times – Slower process compared to injection or blow molding.

- Higher Material Costs – Limited to specific thermoplastics, which can be more expensive.

- Limited to Hollow Parts – Not suitable for solid or highly detailed small components.

- Lower Precision and Tolerance – Less accuracy in dimensional control compared to injection molding.

- Limited Automation – More labor-intensive, leading to higher production costs for large runs.

- Surface Finish Limitations – May require post-processing for a smooth or polished surface.

- Lower Production Efficiency – Not ideal for high-volume production due to longer cycles.

- Thicker Walls Required for Strength – Thinner-walled parts may lack the necessary strength.

- Cooling Time Can Be Long – Extended cooling periods increase overall production time.

Applications of rotational molding

- Storage Tanks – Water tanks, fuel tanks, and chemical storage containers.

- Automotive Parts – Fuel tanks, air ducts, mudguards, and fenders.

- Industrial Containers – Bins, hoppers, and transport containers.

- Playground Equipment – Slides, climbing structures, and outdoor playsets.

- Furniture – Modern plastic chairs, tables, and decorative items.

- Marine & Boating – Kayaks, canoes, buoys, and dock floats.

- Medical Equipment – Enclosures, casings, and patient support devices.

- Agricultural Products – Feed storage bins, water troughs, and irrigation tanks.

- Recreational & Sports Gear – Helmets, cones, and protective padding.

- Road & Traffic Safety – Barriers, traffic cones, and road markers.

- Consumer Goods – Coolers, toolboxes, and custom cases.